Attabotics brought on MistyWest to support ideation and development for adding a supplementary Time-of-Flight (ToF) sensor to their wheeled-ANT robots – with a requirement of 99.999% accuracy.

Background

It’s no surprise that consumer behavior has changed dramatically since the onset of the COVID-19 pandemic, causing a surge in online purchasing and demand for same- or next-day delivery across the globe. While this shift has been occurring, traditional supply chains are struggling to keep up with fulfillment needs, and retailers are seeing smaller and smaller profit margins from their online sales.

Inspired by the framework of ant colonies, Calgary-based Attabotics is a robotics company revolutionizing inventory management systems. Their automated ANT shuttles and patented storage structure–one of Time’s Best Inventions of 2019–utilize both horizontal and vertical space, transforming traditional fulfillment centers into smart spaces, and reducing warehouse needs by 85%.

Attabotics’s wheeled-ANT robots operate on a grid of metal frames with a barcode on each side. Each robot has one camera that scans the barcode, and motion tracking navigation sensors on all four sides gather data on the final positioning of the robot. However, the camera’s sensor is unable to read the barcode if it were to get damaged or obscured.

Looking to increase reliability while maintaining cost-effectiveness, Attabotics brought on MistyWest to support ideation and development for a front-end photometric sensor package to supplement the current barcode scanner. MistyWest would need to prove that use of a Time-of-Flight (ToF) and Photodiode sensor would achieve the same positioning accuracy as the existing barcode scanner, with a reliability of 99.999%.

Attabotics CEO Scott Gravelle. Image source: Globe and Mail

Attabotics’ robotic ANT. Image source: Robot Report

The Solution

ToF technology has gained momentum due to the rise of occupancy (people) monitoring for social distancing, but is most often used in automation, thanks to its high processing speeds and accuracy.

A ToF sensor scans the rails to determine the distance from the rail for final positioning. This comes with its own set of challenges; any interference between a light signal and object will cause a change in its value, so any debris, external light sources and reflections will impact accuracy.

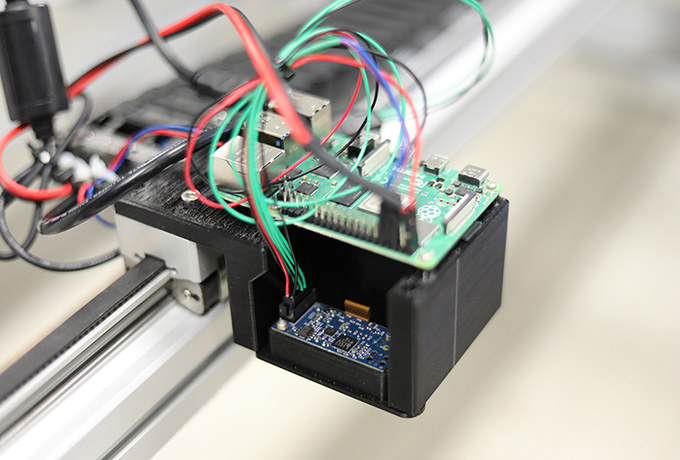

Using a first principles approach, MistyWest took the purely visual challenge of “how do we know where we are?” and broke it down into pattern recognition that would supplement the existing optical solution of the ANT. MistyWest organized, classified and mapped out this data, and evaluated the sensor suite’s performance on a custom developed “robot-analog” to investigate the effect of lighting conditions, reflections and debris at different acceleration profiles.

Outcomes

An analysis algorithm and pattern recognition data collection were implemented to reach the required accuracy and reliability of 99.999% for grid detection, using a calibrated front-end photometric sensor package.

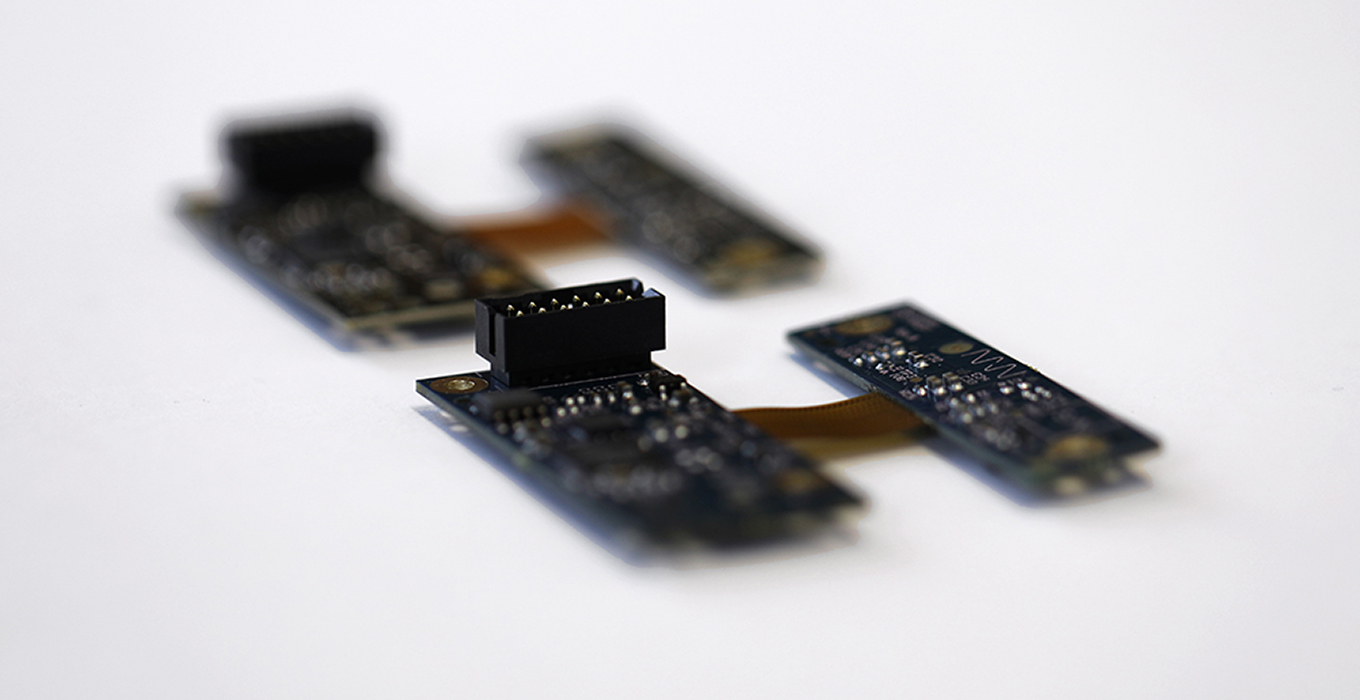

MistyWest designed and assembled 150 photometric sensor boards and shipped a total of 128 units, which integrated neatly with the Attabotics system and required minimal redesigns. The project was completed within 9 months to meet certification and testing schedules; all amid global manufacturing and supply chain crises.

Components with availability for the next 3 years were selected to coincide with Attabotics’ upgrade schedules and growth strategy, as the automation of smart spaces in supply chain management plays a crucial role in the evolving manufacturing landscape.

The photometric sensor suite is currently being A/B tested by Attabotics in real-world scenarios with ongoing support. It has potential for extended use beyond localization, as the collection of data points can be classified and fed into an ML pipeline, enabling a smarter and more autonomous localization directly onboard the robot. ToF sensors can also potentially detect obstructions and damaged grids, allowing greater quality control and maintenance.

The ToF sensor suite MistyWest designed for Attabotics